This type of wire rope hoist has its particular advantage for compact quadrate structure and internal configuration. The planetary gear reducer is adopted to ensure high transmission efficiency. It is characterized by low noise, compact structure, omitting the intermediate shaft. The square appearance is easier to install and fix. In addition, the lifting hook is designed to prevent accidental slippage; Motor has the thermal protection device, which will automatically cut off to prevent damage when the temperature is too high.

With the ideal design, we can ensure high safety as well as working efficiency. Load limit protection device is optional to avoid overload-induced adverse consequences.

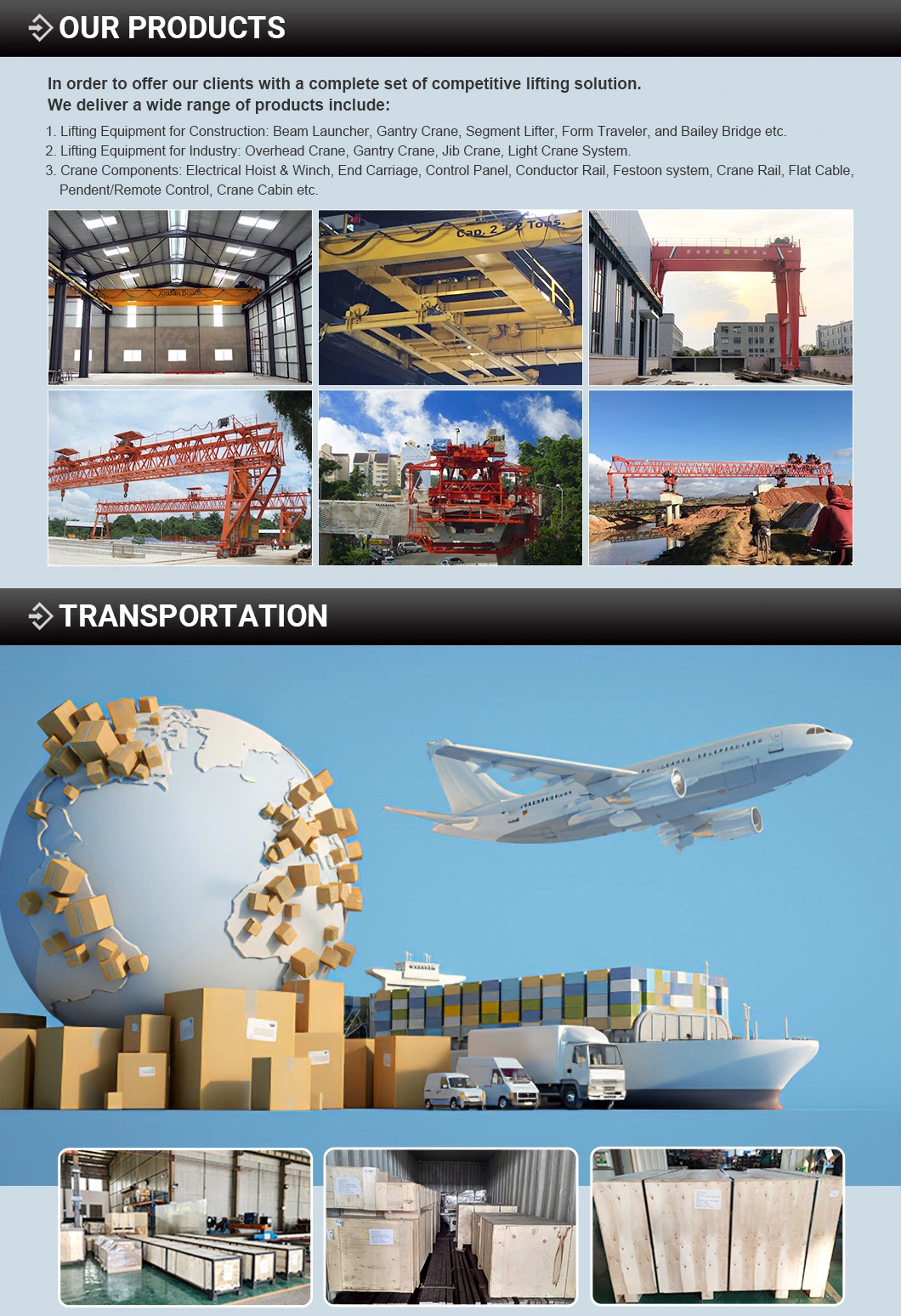

Features:

1). Steel rope electric hoist, newest design with quadrate outline, modularized Construction, and good unitized capability

2). The fundamental mode change combine is very convenient and multiform

3). The special drive composition method is very stationary which saves the usual long transmission shaft

4). The reducer use plant speed-down drive is highly effective, low noise and long lifespan

5). Unique column rotor-taper breaking wheel motor with disk is low noise and reliable

6). With the advanced technology from overseas, the guide rope unit is very reliable and safe

7). High precision and super mechanical spin limit

8). High quality electric control component with low malfunction

9). The products from 400kg to 50mt, complying with the international standard

Application area

Whether chain hoist or wire rope hoist, electric or pneumatic; Our line of powered hoists are ideal in manufacturing, power generation, and industrial facilities where heavy items are lifted and positioned as part of production or warehousing. Our new model high-capacity wire rope hoist complements our line with capacities up to 50 tons. We offer a full line of manual hoists, both hand chain and lever tools, which are used primarily for maintenance and construction activities.

1 ton thru 5 ton electric hoists

3 ton thru 15 ton monorail wire rope hoists

5 ton thru 40 ton top running wire rope hoists

Custom built hoists:

1. Various capacities

2. Double girder, monorail, jib cranes etc.

3. All types of open winches

4. Polar trolley hoists

5. Critical lift

6. Twin hook

7. Quadruple hook

8. Explosion proof

9. Indoor or outdoor use

10. Transfer cars

11. Hazardous locations

12. Two drum bucket

13. Automated hoisting systems

14. Hot metal steel mill hoists - AC/DC

Selection Criteria

The size of the hoist is determined by the load spectrum, average operating time, safe working load and rope reeving.

1. What are the operating conditions?

2. What is the specified safe working load?

3. To what height must the load be lifted?

4. What is the required lifting speed?

5. Do the loads need to be lifted and lowered with great accuracy?

6. Is horizontal load travel necessary?

7. How the hoist to be controlled?

With the ideal design, we can ensure high safety as well as working efficiency. Load limit protection device is optional to avoid overload-induced adverse consequences.

Features:

1). Steel rope electric hoist, newest design with quadrate outline, modularized Construction, and good unitized capability

2). The fundamental mode change combine is very convenient and multiform

3). The special drive composition method is very stationary which saves the usual long transmission shaft

4). The reducer use plant speed-down drive is highly effective, low noise and long lifespan

5). Unique column rotor-taper breaking wheel motor with disk is low noise and reliable

6). With the advanced technology from overseas, the guide rope unit is very reliable and safe

7). High precision and super mechanical spin limit

8). High quality electric control component with low malfunction

9). The products from 400kg to 50mt, complying with the international standard

Application area

Whether chain hoist or wire rope hoist, electric or pneumatic; Our line of powered hoists are ideal in manufacturing, power generation, and industrial facilities where heavy items are lifted and positioned as part of production or warehousing. Our new model high-capacity wire rope hoist complements our line with capacities up to 50 tons. We offer a full line of manual hoists, both hand chain and lever tools, which are used primarily for maintenance and construction activities.

1 ton thru 5 ton electric hoists

3 ton thru 15 ton monorail wire rope hoists

5 ton thru 40 ton top running wire rope hoists

Custom built hoists:

1. Various capacities

2. Double girder, monorail, jib cranes etc.

3. All types of open winches

4. Polar trolley hoists

5. Critical lift

6. Twin hook

7. Quadruple hook

8. Explosion proof

9. Indoor or outdoor use

10. Transfer cars

11. Hazardous locations

12. Two drum bucket

13. Automated hoisting systems

14. Hot metal steel mill hoists - AC/DC

Selection Criteria

The size of the hoist is determined by the load spectrum, average operating time, safe working load and rope reeving.

1. What are the operating conditions?

2. What is the specified safe working load?

3. To what height must the load be lifted?

4. What is the required lifting speed?

5. Do the loads need to be lifted and lowered with great accuracy?

6. Is horizontal load travel necessary?

7. How the hoist to be controlled?

| Model | Lifting Capacity (t) | Working Duty | Lifting Motor Power(kw) | Lifting Speed (m/min) | Dimension | L | A | AO | B | Hmin | L1 | Wheel Diameter (mm) | |||||

| 6m | 9m | 12m | 18m | 24m | 30m | ||||||||||||

| SH2A(2/1) | 0.5 | M4 | 1.1 1.1/0.3 | 9 9/2.2 | L | 534 | 661 | 678 | 813 | 948 | 1083 | 256 | 192 | 244 | 410 | 281 | 13 |

| LO | 223 | 291 | 358 | 493 | 628 | 763 | |||||||||||

| S | 66 | 99 | 132 | 198 | 264 | 330 | |||||||||||

| SH3A(2/1) | 1 | M4 | 1.5 1.5/0.4 | 8.5 8.5/3.2 | L | 886 | 983 | 1080 | 1274 | 1468 | 1662 | 264 | 194 | 244 | 430 | 390 | 18 |

| LO | 324 | 421 | 518 | 712 | 906 | 1100 | |||||||||||

| S | 96 | 144 | 192 | 288 | 384 | 480 | |||||||||||

| SH4-2/1A | 2 | M4 | 3 3/0.8 | 7.3 7.3/1.8 | L | 1032 | 1136 | 1240 | 1449 | 1657 | 1866 | 325 | 245 | 300 | 520 | 462 | 18 |

| LO | 389 | 493 | 597 | 806 | 1014 | 1223 | |||||||||||

| S | 104 | 156 | 209 | 313 | 417 | 521 | |||||||||||

| SH5-2/1A | 3 | M4 | 4.5 4.5/1.0 | 7 7/1.6 | L | 1160 | 1279 | 1379 | 1597 | 1815 | 2033 | 360 | 280 | 335 | 600 | 550 | 18 |

| LO | 414 | 524 | 633 | 851 | 1069 | 1287 | |||||||||||

| S | 110 | 164 | 219 | 328 | 437 | 546 | |||||||||||

| SH6-2/1A | 5 | M4 | 7.5 7.5/2.0 | 7.3 7.3/1.8 | L | 1235 | 1350 | 1464 | 1693 | 1922 | 2151 | 403 | 309 | 370 | 700 | 550 | 22 |

| LO | 459 | 574 | 688 | 917 | 1146 | 1375 | |||||||||||

| S | 118 | 177 | 236 | 354 | 472 | 590 | |||||||||||

| SH7-2/1A | 8 | M4 | 13 13/3.2 | 8 8/2 | L | 1473 | 1590 | 1706 | 1939 | 2172 | 2405 | 470 | 350 | 440 | 760 | 725 | 26 |

| LO | 505 | 622 | 738 | 971 | 1204 | 1473 | |||||||||||

| S | 117 | 175 | 233 | 350 | 466 | 583 | |||||||||||